Energy International USA is your manufacturing solutions provider. Energy operates its own world-class, full-service, design and build organization in the United States providing customers worldwide with the highest degree of innovative engineering, reliability, maintainability and value.

Our Services

Engineering

Energy Offers a full range of engineering services including Animation of 3D Models, CAD Simulations, Creation of Control Schematics, Creation of Equipment and Systems Manuals, Creation of Facility Layout, Creation of Preventative Maintenance Manuals, Data Translations, Engineering Solution Consulting, Inspection Systems, Interpretation of 3D CAD Data, Manufacturing Solution, Consulting\Plotting, Process Review, Conversion of Existing Drawings to CAD, Reliability and Maintenance Studies, Robotic Interface and Programming, Simultaneous Engineering Studies, Total Program Management, Total Project Management and Virtual Prototyping.

Manufacturing

Energy offers a full suite of in-house manufacturing support services including Project Design, Build and Programming, Project Management, Installation, Field Service and Maintenance, IT Support and Project Administration.

Solution Consulting

Energy’s consulting teams have the experience, creativity and brainpower necessary to solve your manufacturing and engineering problems. Our consulting teams are solution oriented and place great emphasis on cost effectiveness in order to obtain results.

Project Management

Our project management team leads and delivers. They listen to your needs, respond appropriately and help to achieve optimal solutions which address all specifications, safety, ergonomic issues and budget and delivery requirements.

Application Expertise

When it comes to application expertise, we cast a very wide net spanning many types of applications and production environments. Our experience in rolling, sawing, welding, forming, cutting, spraying and a diverse range of other process methods make us uniquely qualified for a wide range of applications. More importantly, our mechanical, chemical and controls expertise allow us to seamlessly integrate any number of methods into a complete and coordinated system.

Special Machines

Energy international Manufacturing USA has provided engineering solutions for our manufacturing customers. Below are several examples of our engineering expertise.

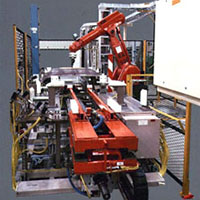

Process Automation

Washing & Deburring

These machines use water jets, air knives and drying jets to completely clean out worm trails, drilled holes and the flat, ground faces for cast-aluminum transmission valve bodies. The machine also features a 60-pallet-capacity transfer system and an automatic bushing press station.

Headliner Adhesive

The three-station machine automatically applies adhesive to automotive headliners. It incorporates a 6-axis ABB robot programmed to accommodate both standard and sunroof style headliners installed in four different car models.

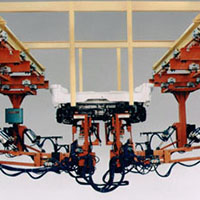

Assembly Systems

Rear Axle Assembly

Rear axle installation is facilitated by four counterbalanced, air-operated handling systems that produce zero gravity for unusually easy operation.

Front Knuckles

The front knuckler assembles three major components: the cast iron knuckle, a dust cover and a hub.

Ergo-Arm Systems

The pneumatically-operated fixture is a modular device consisting of a welded frame, cross-arms, locating blocks, slides and clamps. It is used to move the front bumper into its designed position next to the fascia as the vehicle moves down the line.

Pin Press Machines

Two single-station machines insert a 1.5-inch long pin that joins two halves of a steering column. Precise alignment of the components facilitates pin insertion and helps ensure ultimate integrity of the complete assembly.

Rear Strut Assemblies

Single station machines assemble multiple parts of the strut using pneumatically-actuated fingers to automatically control spring compression as the unit is assembled.

Coating & Painting

Energy International has designs and builds many types of paint systems from full coverage, to precision paint systems, to hand-held units for offline or lab applications. Large or small, automatic or manual, Energy can design a system that best suits your needs.

Test Systems

Energy International designs and builds Test Equipment and Systems that cover a wide range of applications including: Functional Testing, Non-Destructive Testing, Destructive Testing and Life Cycle Testing

Transfer Systems

Front Cross Member

This assembly features special build-up fixtures, precise part holding and an ergonomically-correct counterbalanced lifting device serving as a mounting platform for the vehicle’s steering gear, sway bar, control arms and reinforcement plate.

Buffer Storage

These units store stamped parts as they are passed through a stamping line from one press to another. Panels are stacked up to 20 high and are moved automatically as the next press in line press calls for parts.

Handling Windshields

Windshields for various vehicles are handled smoothly and efficiently with an automated conveyor and storage system that moves the windshields from a bending oven to a washer on a just-in-time basis.

Wheel/Tire Flipper

These units store wheel and tire assemblies feeding them to the final assembly area on two roller conveyors in the correct sequence.

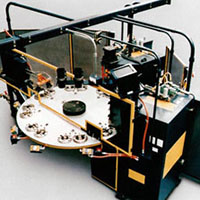

Precision Welding Systems

Multi-station precision-welding machines are designed to accurately weld small assemblies. A machine vision system and precise fixturing are designed to achieve correct alignment. Fixture design facilitates easy modification to accommodate changes in part configuration.

Windshield Sealing

The ultimate purpose of the glass sealing system is to establish the correct installation forces and time necessary to achieve proper and consistent windshield and rear window sealing.

Lifting and Handling

Energy’s Ergo-Arms are designed and built for numerous applications throughout the assembly process. The arm pictured is used to insert and center instrument panels in body-in-white as they move down the assembly line.

Leaf Spring Bushings

This two-stage machine assures the fast and accurate insertion of rubber bushings in rear leaf springs.

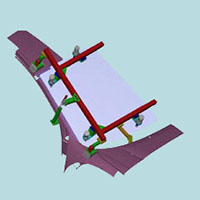

3D Product Data

Energy utilizes 3D modeling to develop engineering and manufacturing assembly tooling designed around customer integration of CAD, surfacing, animation and translation capabilities for a variety of sources.

Inspection

To ensure that quality is built into every process, inspection has to be a fundamental part of all manufacturing operations. Energy is proficient in the design of offline and inline inspection systems. Our expertise in mechanical, chemical and electrical engineering allows us to design the system that will help you achieve the desired output.

Lubrication

Energy has in-house Chemical and Process Engineering capabilities with strong expertise in lubrication processes as well as chemical lubricant development. We are accustomed to working with everything from traditional forming oils to high-pressure applications as well as lubricants that lend themselves to thermal degreasing. We understand that lubrication technology is an essential part of making your operation flow as smoothly as possible. That is why storage is another essential part of using equipment like this with Storemasta cabinets being utilized in the areas of operation for safe access.

Material Handling

At Energy, we understand that material handling is crucial for transferring an assembly or component to the next stage in the production process. Our material handling systems have accommodated the handling and packaging of very small components such as nuts and screws to large automated methods for handling red hot extruded steel or moving die plates in and out of large stamping presses. Our staff are fully trained so no matter if they need to use a hand truck Greensboro or forklift, the materials are in safe hands. We welcome the opportunity to utilize our innovative engineering creativity to support your material handling requirements.

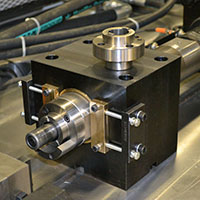

Swaging

Energy International has developed a series of manufacturing systems to support these swaging operations. The output and capacity of these units can vary from lower volume low force units to higher force units that may perform multiple swaging operations concurrently.

Tube Processing

Utilization of the Energy Method is critical to the configuration of a tube processing system. We work with our customer’s specific requirements to determine the optimum combination of processes and methods to achieve the end product with volumes and model mix that maximize the value provided to the customer.

Heat Exchange

Energy International designs and builds our own line of high-precision Fin Presses, Fin Mills and Core Builders. We support these machines with our line of Fin Press and Roll Form Tooling. We can also address many other needs such as Tube Stuffers, Fin Plyers, Fin Trayers, Fluxing Systems, Transfer Systems and much more. In combination with our unique abilities in special machines, we can support heat exchange operations from start to finish.